«MYTHEN» revolutionizes Hydrogen Production

Our groundbreaking new membrane is setting unprecedented standards in alkaline water electrolysis (AWE). Combining cutting-edge materials with unmatched performance, we’re transforming the future of sustainable hydrogen production.

«The Next-Generation Membrane for Alkaline Water Electrolysis»

Our Innovation transforms Hydrogen Production:

Achieve the lowest resistance on the market—drastically reducing H2 production costs.

The first pure polymer membrane for AWE—extremely durable and stable.

No pre-moistening required—saving time and simplifying operations.

Enables automated stack assembly, reducing costs and errors.

Lower CAPEX and paving the way for sustainable hydrogen production.

Why the MYTHEN Membrane is a Game Changer

- Unrivaled Efficiency

Achieve the highest electrolysis efficiency on the market. With ultra-low resistance, our membrane slashes hydrogen production costs while boosting output.

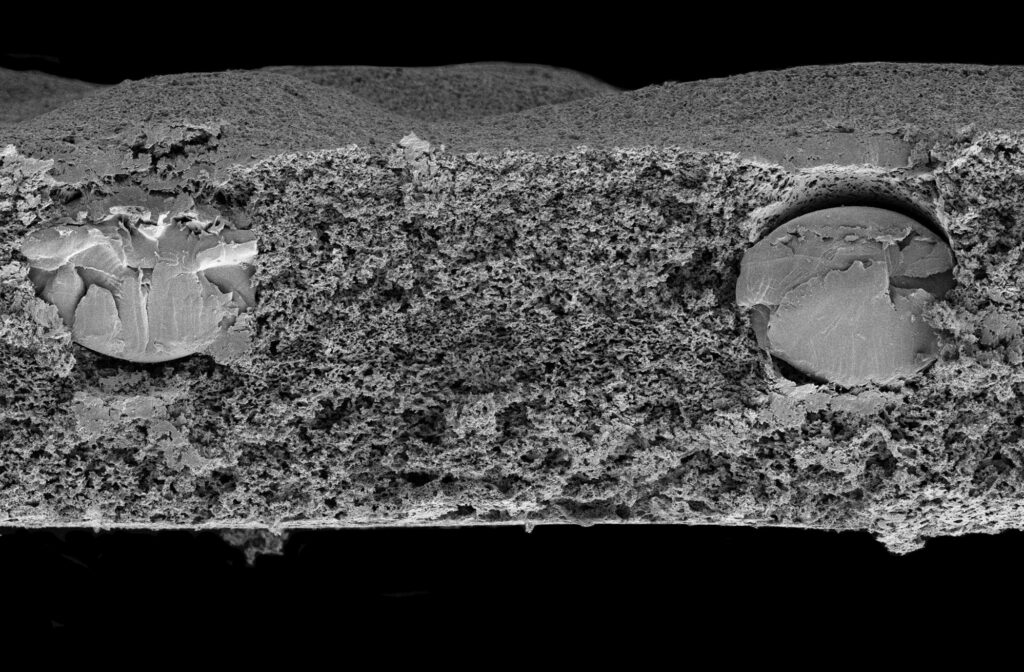

- Breakthrough Material Technology

Introducing the first-ever pure polymer membrane designed exclusively for both pressurized and non-pressurized AWE. Experience outstanding durability, mechanical stability, and performance in challenging electrolyte environments.

- Ready-to-Use Convenience

Unlike conventional membranes, MYTHEN is delivered dry and ready for immediate installation—no pre-moistening required. Simplify your operations while maximizing uptime.

Redefining Automation and Cost Efficiency

- Seamless Stack Assembly

Our membranes are weldable and bondable, paving the way for automated stack assembly. Say goodbye to labor-intensive manual setups and hello to faster, more precise production. Reduce errors, cut costs, and improve safety in your electrolysis processes.

- Efficiency That Cuts Costs

By boosting electrolysis efficiency, we deliver measurable savings in hydrogen production—benefiting manufacturers, end-users, and the planet.

Be part of the hydrogen revolution - today.

«MYTHEN» – A Smarter, Sustainable Choice

Our pure polymer membranes outperform traditional ceramic solutions, offering better adaptability for automated processes and significantly lowering CAPEX. By choosing this transformative technology, you’re not just optimizing performance; you’re contributing to the global shift toward clean, sustainable energy.